graINspect Lab

This laser-based Particle Size Distribution (PSD) analyzer is a stand-alone package of ease of use, state-of-the-art PSD analysis algorithms and first-class support and customization options.

The analyzer is an autonomous device designed for probles of granular materials (1…30mm fraction) of several kilograms with manual loading. It can be used for

routine on-site analyses,

cross-checking of other analyses techniques (such as sieve analysis),

evaluation of prospective continuous conveyor monitoring with laser.

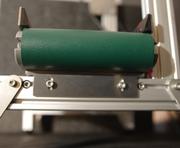

Wet, sticky, dirty materials are handled safely; the conveyor belt is made from low-abrasion, water-resistant material, its electronics is encapsulated. Scraper at belt return can be positioned to clean the belt from sticky residues. There is enough space both under the scraper and discharge cylidner for various collection containers. Feet are foldable (for transport) and can easily be exchanged for a longer type.

The device comes in industrial-grade case and can be assembled (and later disassembled) in a few minutes with tools included.

High-precision (<0.1mm) laser scanner works in tandem with precise conveyor band. As a safety measure, the conveyor motor is programmed with torque limitation, to be sufficient for probe transport but cause no harm in case of accidental operator contact. Laser data are fed to the computer which is able to reconstruct the material surface with high accuracy for subsequent analysis.

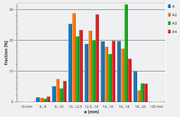

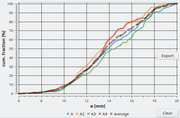

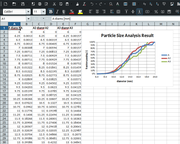

The analysis runs on preinstalled computer using our specialized software. Several analysis algorithms are provided out of the box. One family of analyses identifies each grain while other processes the measurement in a global fashion (fractal and spectral analysis). Quick data presentation (cumulative size distributions, histograms, average PSD, …) is provided, with the possibility of exporting data in standard formats (such as XLS, but also raw data for scientific visualization); integrations with your workflow are available as enhancement.

The software can self-update itself over the air (only if requested by the user). Raw recorded data can be easily submitted to us, should you need adjustment of analysis algorithms to your particular material — without having to send physical sample to us.

Do not hesitate to contact us for inquiries.